To reduce air turbulence and prevent splatter or unnecessary spread of aerosols, a proper technique should be used when working within a Class II Biological Safety Cabinet (BSC).

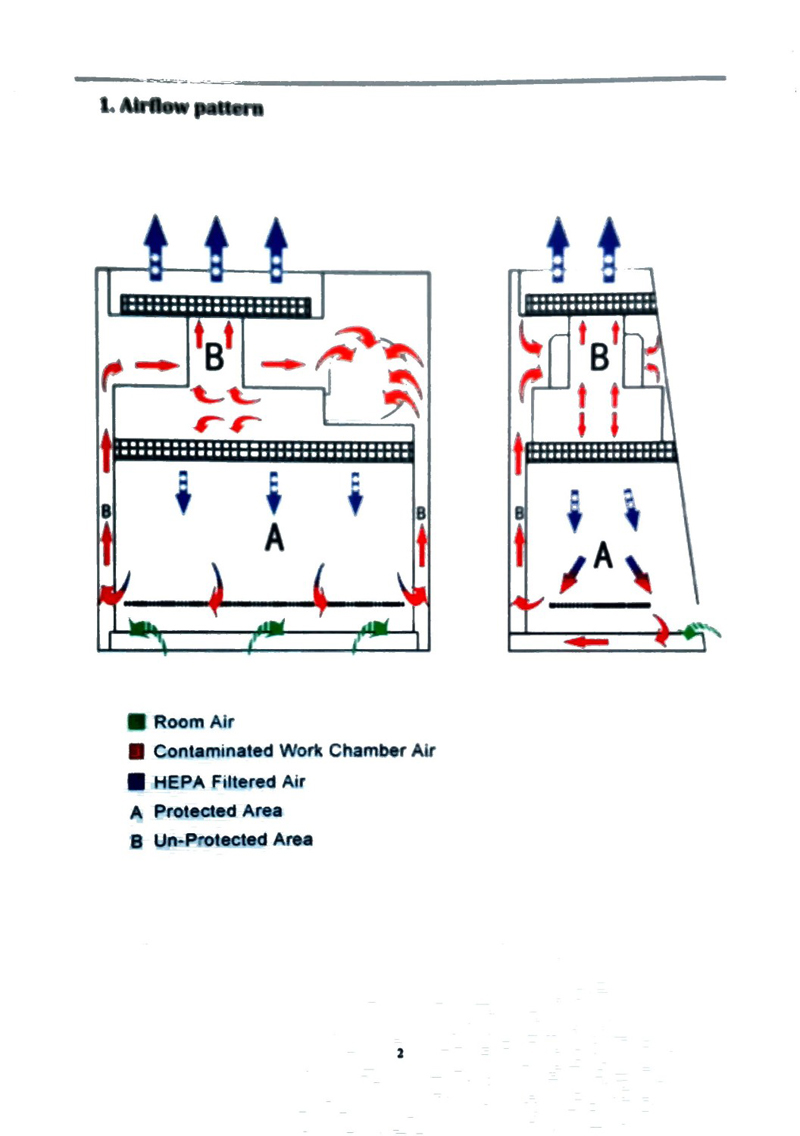

1. Know the airflow

BSCs offer protection to product, personnel, and environment via the use of HEPA-filtered air. In order to maintain a safe work environment, it is important to understand the air flow in, out, and through the cabinet.

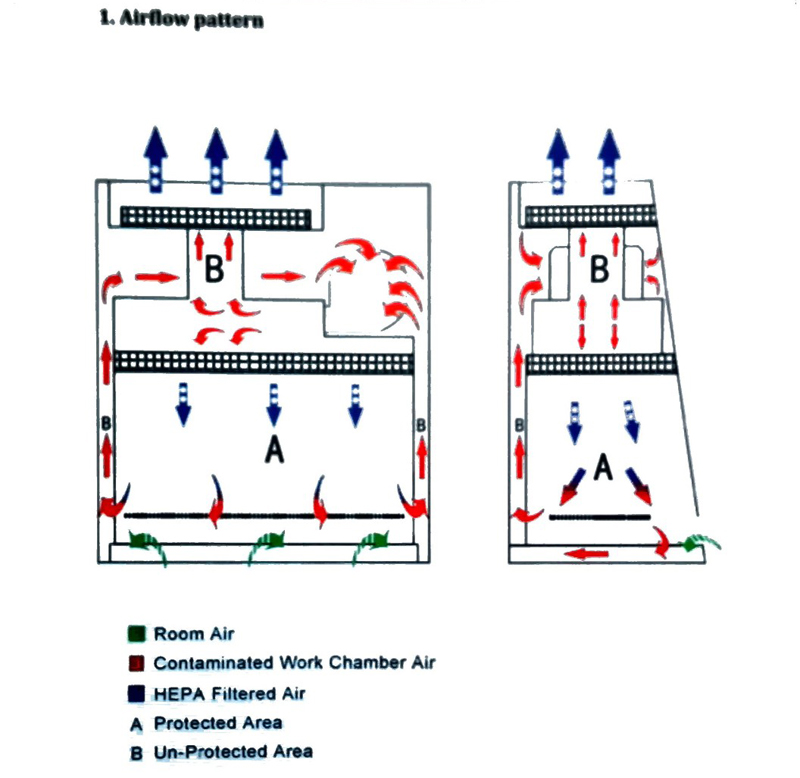

2. Work at the proper sash level

When the glass viewing sash is open to the certified height, optimum air inflow velocity (personnel protection) is obtained.

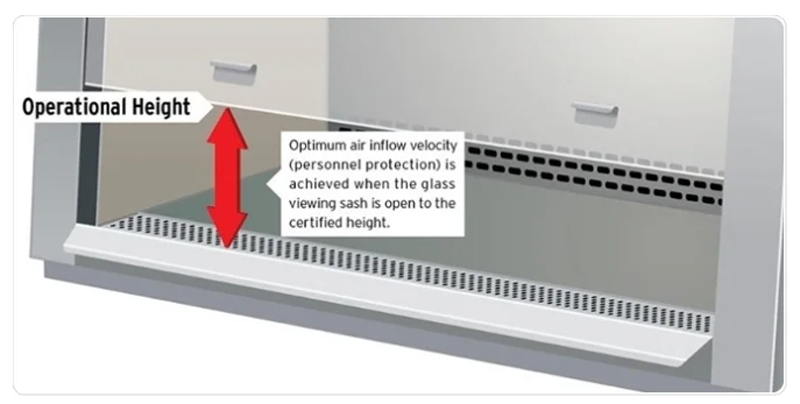

3. Never cover the air grill

If the air grill at the front of the cabinet is covered, it will affect the airflow integrity and may allow the laboratory air to infiltrate the work zone, or even cause the work zone air to enter the laboratory space.

Arms tend to block the grill but this can be prevented with a properly designed recessed airflow grill and/or a OLABO elbow rest.

OLABO elbo rest

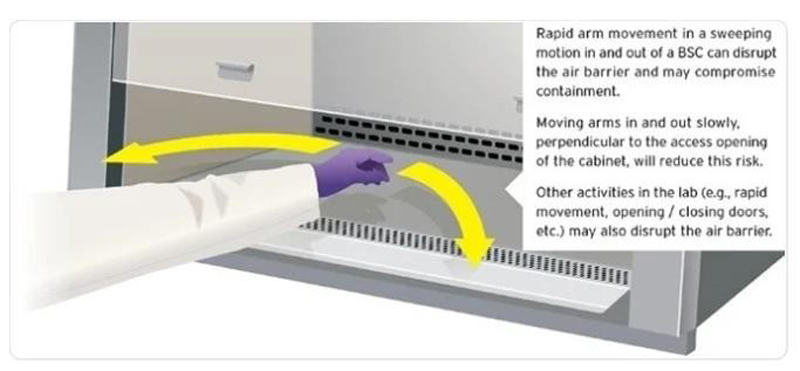

4. Minimize rapid movement

When arms are rapidly moved in a sweeping motion in and out of a BSC, this can disturb the air barrier and thus affect the containment. This risk can be reduced by slowly moving the arms in and out, perpendicular to the cabinet’s access opening. The air barrier may also be disrupted by other activities in the laboratory (for example, rapid movement, closing or opening doors, etc.).

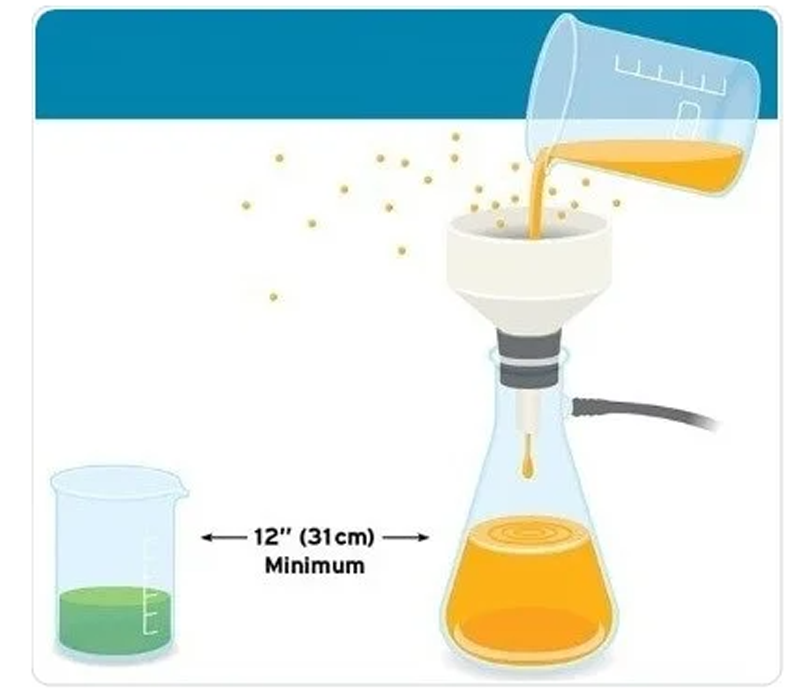

5. Reduce splatter

Many standard procedures performed in BSCs may produce splatter or aerosols. Methods to reduce the generation of splatter and aerosols will reduce the possibility for personnel exposure to infectious materials.

Class II cabinets have been specifically designed so that laminar air flow will capture horizontally nebulized spores within 14 inches (35 cm) of travel. Generally, potential cross-contamination can be minimized by keeping clean materials at a minimum distance of 12 inches (31 cm) away from activities which are likely to create aerosols.

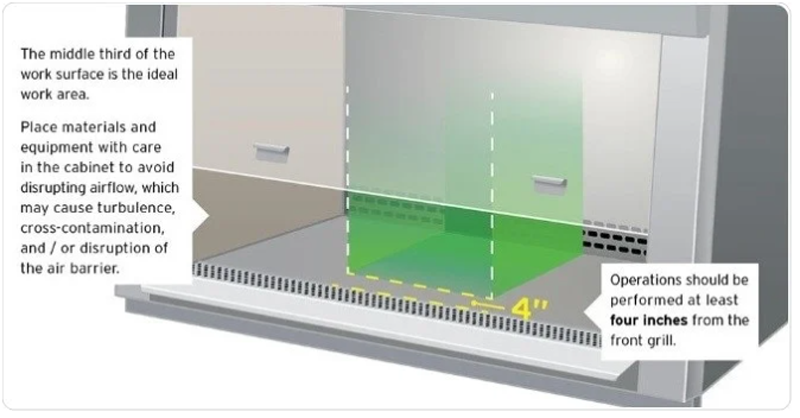

6. Know the work area

The ideal work area is the middle third of the work surface.

Both equipment and materials should be carefully placed in the cabinet to avoid any disruption to air flow, which may lead to cross-contamination, turbulence, and/or disruption of the air barrier.

It is important that operations are carried out at least four inches from the front grill.

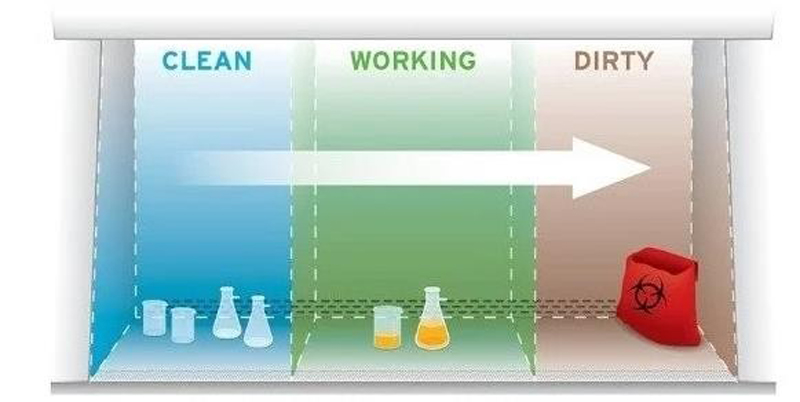

7. Work from clean to contaminated

Active work must flow from the clean area to the contaminated area across the work surface. Both materials and supplies should be positioned in such a way that there is limited movement of “dirty” items over “clean” ones.

In order to prevent airflow imbalance within the work zone, proper balance of materials should be maintained from left to right. Large and bulky items like suction collection flasks, discarded pipette trays, and biohazard bags should be placed to one side of the cabinet’s interior.

It is important that all materials are placed as far back in the cabinet as possible, away from the front grille of the cabinet and toward the rear edge of the work surface. In the same way, aerosol generating equipment (for example, tabletop centrifuges, vortex mixers) should be located toward the rear of the cabinet in order to benefit from the air split.

8. Working with tubes

Open tubes or bottles should never be held in an upright position. Similarly, tube or bottle caps should not be placed on the toweling, and items should be covered or recapped as soon as possible.

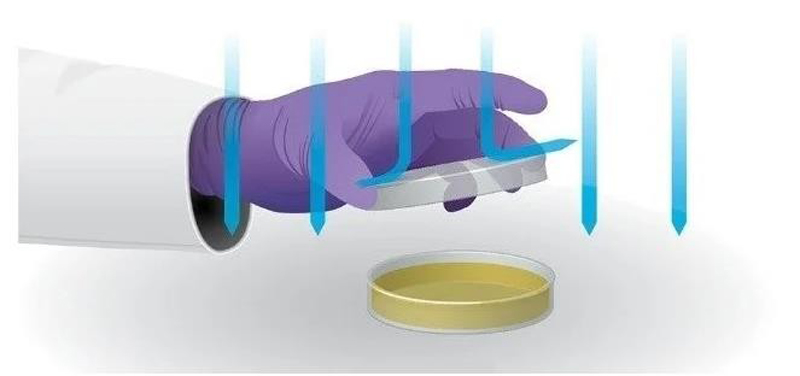

9. Working with petri dishes

When working with tissue culture plates and petri dishes, the lid should be held above the open sterile surface in order to reduce direct impaction of air downflow.

10. Working with aspirator bottles or suction flasks

Suction flasks or aspirator bottles should be coupled to an in-line HEPA (or equivalent) filter, and an overflow collection flask containing suitable disinfectant. This combination not only offers protection to the vacuum pump or vacuum system in the facility, but also to the staff who services the equipment.

Post time: Oct-19-2021