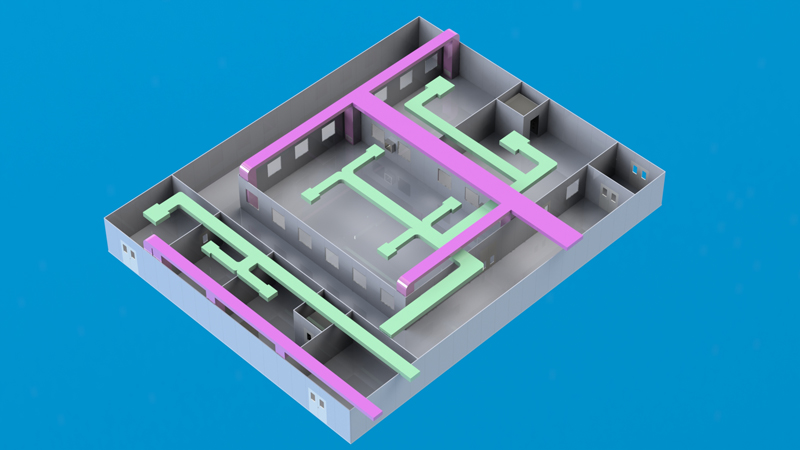

Class 1,000 Manufacturing Clean Room

Class 100,000 Manufacturing Clean Room

Class 100,000 Clean Room adopts the following measures:

1. Air conditioning system must consist of three-level air filtration: primary efficiency, middle efficiency and high efficiency filtration, securing that the clean air flow into rooms and diluting polluted air indoors.

2. The pressure indoors should be maintained to prevent the interference of outside air. General industrial clean room requires a pressure dfference of 5~10Pa between the indoor and outdoor.

3. Building envelope must be of good air tightness. The surface is smooth, dustless and air-tight.

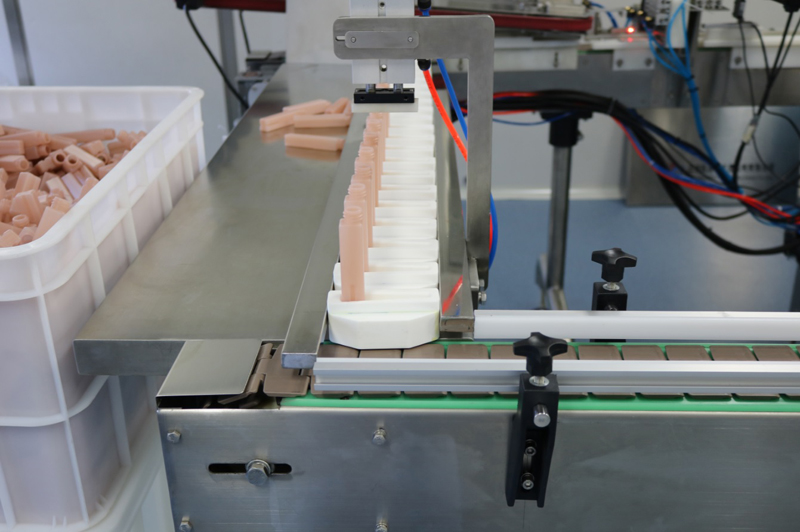

Class 10,000 Reagent Production Workshop

Thermostatic and Humidistatic purified air unit ensure the production environment meets the standard requirements, remote control and real-time display are convenient to monitor production environment. Energy-saving module design can more effectively reduce production costs.